PV Glass Interleaving Paper Description

|

Brand

|

BMPAPER

|

|

Paper type

|

Industrial special paper

|

|

Color

|

White, brown

|

|

Basic grammage

|

28g 32g 36g 38g 40g 50g etc

|

|

Feature

|

Anti Rust, durable, PH<7

|

|

Size

|

300 - 2500mm, customized

|

|

Usages

|

For PV Glass protection, Separation during production, packaging and transportation

|

|

Lead time

|

25 - 35 working days

|

|

Loading capacity

|

15 - 16tons for 20ft container, 26 - 27tons for 40ft container

|

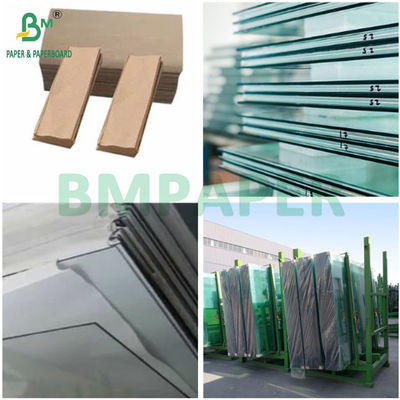

PV Glass Interleaving Paper Show

PV Glass interleaving paper has specific applications in the glass further processing industry. This

material is mainly used to protect flat glass during production, transport and installation from scratches

or contamination by preventing direct contact and adhesion between glass panes.

PV Glass Interleaving Paper Feature and Application

Feature:

1. Surface treatment: Glass spacer is usually specially treated to give it good smoothness and isolation

properties,which can effectively reduce the friction between the glass and at the same time prevent the

coatings on different glass surfaces from contacting each other and being damaged.

2. Physical properties: it needs to have a certain degree of strength and toughness, to be able to maintain

stability when picking up and placing the glass and can withstand a certain temperature change without

deformation or damage.

3. chemical stability: in order not to react with the glass surface substances, the spacer needs to have

excellent chemical stability, does not contain corrosive components, will not have a negative impact on the glass.

4. Environmentally friendly: high-quality Glass interleaving paper may also be designed to be easy to peel

and no residue, can be easily cleaned up after use, and some products are even biodegradable to reduce

the impact on the environment.

Application:

● In the manufacture of multi-layer insulating glass, it is placed as a spacer material between two or more

pieces of glass,keeping them separate from each other until the sealing process is complete.

● Used as a separator between each piece ofglass when stacking flat glass for storage and transport,

preventing scratches and breakage due to movement and compression.

● In the production of large glass substrates such as liquid crystal displays (LCDs) and organic light-emitting

diodes (OLEDs), it is used for temporary protection and positioning to ensure a high level of cleanliness

and damage-free handling during the production process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!